From June 27th to 30th, the 18th China International SME Expo (hereinafter referred to as "China Expo"), jointly sponsored by the Ministry of Industry and Information Technology of China, the State Administration for Market Regulation and the People's Government of Guangdong Province, was held in Guangzhou. As an international exhibition certified by the International Exhibition Alliance (UFI), it focuses on the achievements of equipment manufacturing, electronic information, new materials and new energy industries, creating a feast of cross-industry exhibition, exchange and cooperation.

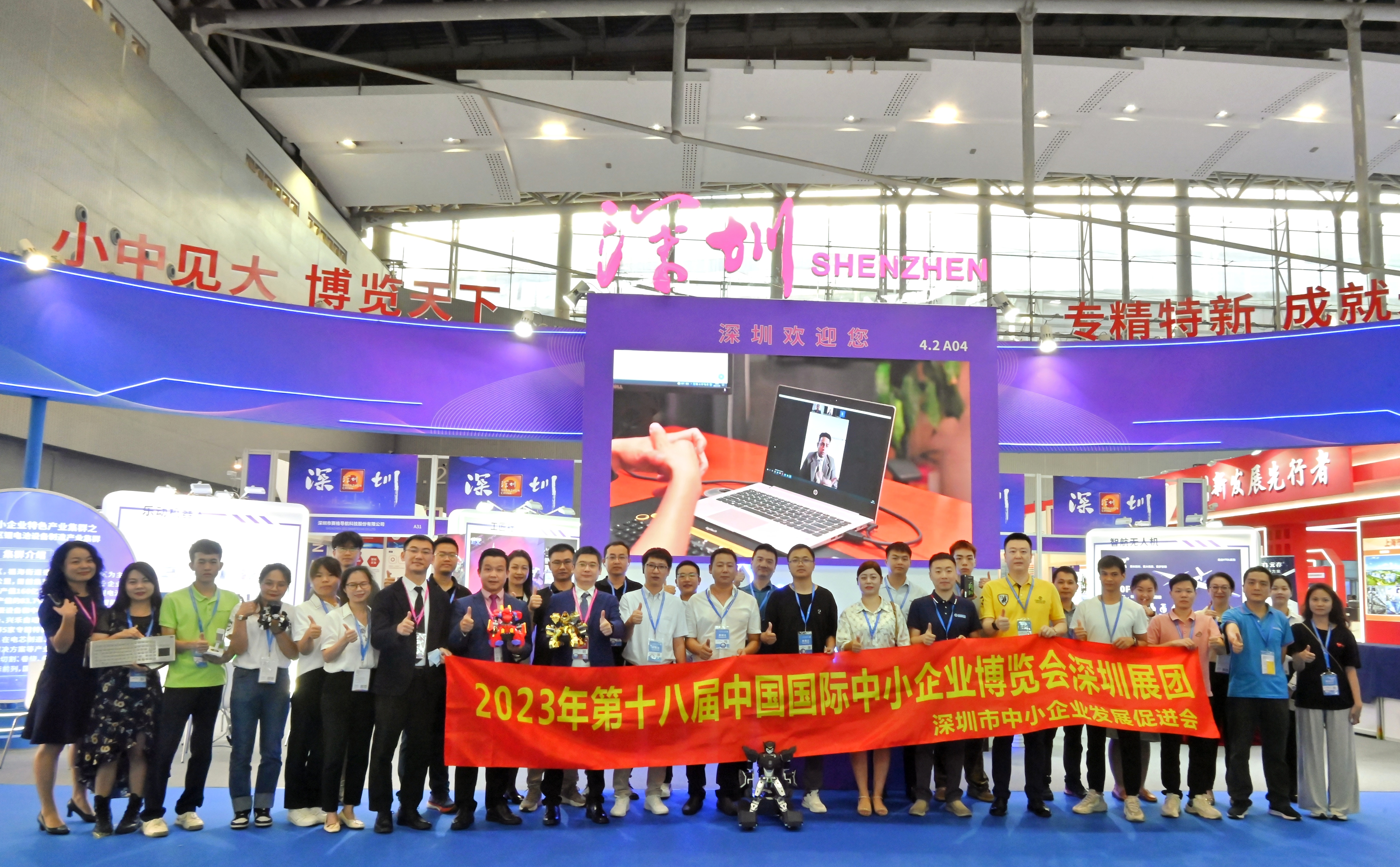

As a key enterprise specializing in specialization, refinement and innovation in Shenzhen, SEG was invited to participate in the comprehensive image exhibition area of Shenzhen equipment manufacturing, demonstrating the strong capabilities of supply chain management, manufacturing and production, as well as one-stop solutions from electronic product design to finished product delivery, and conducting in-depth exchanges and cooperation with domestic and foreign technology enterprises and professionals.

SEG practices innovation-driven strategy, continues to forge "specialized, special and new" technologies and products, the company has passed IATF16949, ISO9001, ISO45001, ISO14001, GB/T27922, ISO20000 and other QMS and EMS management system certification, combined with its own advantages in the manufacturing business sector, focusing on automotive electronics, smart home/wearable, consumer electronics industry, always adhering to the concept of manufacturing high-quality products, guided by high quality standards. Produce high-quality and competitive products, and establish the development direction of one-stop solutions for OEM/ODM design and manufacturing through the deep integration of innovative design and advantageous manufacturing.

SEG is committed to promoting the development of manufacturing automation and informatization, through the industrial Internet of Things, big data analysis technology and the introduction of automation equipment, to achieve equipment interconnection and intelligent collaboration, improve production efficiency and working environment safety. At the same time, the traditional manufacturing process is digitized, and the management efficiency of production planning and quality control is improved, so as to promote the transformation and upgrading of manufacturing level, and provide customers with high-quality and efficient product manufacturing solutions.